One of the tools to beat competitors is quality. If you are providing top-notch quality than that of your competitors, you will have a competitive edge.

Brand loyalty is no more nowadays unless they maintain the quality. Six sigma is simple words are zero defects, but 100% efficiency is not possible, and hence it is something negligible or near to zero like 10,00,000 pieces will produce only 3.4 defective pieces.

Quick Navigation

What is Six Sigma?

Six Sigma is a business management strategy that combines the most effective and efficient aspects of several different quality control innovations. This strategy asserts that manufacturers can exercise total control over their business by emphasizing the teamwork and commitment of staff at every level. All aspects of production can be gauged by incorporating these ideas, thereby allowing quality monitoring at every stage.

History of Six Sigma

As you can see below, Engineer Bill Smith was first introduced while working in Motorola in 1987. He got 10x reductions in product failure in 5 years there.

After that, other companies like;

- Allied Signal – 1992

- General electric – 1995

- Ford, Nissan, and others – 2002

Nowadays, six sigma is not confined to big giants, and every firm can train its workers. All production units are following Six sigma with lean technology. Both are developed in Japan.

How Six Sigma Works?

We will discuss all this with a simple scenario.

First of all, we have to set the target and

Upper Specification Limit – USL

Lower Specification Limit – LSL

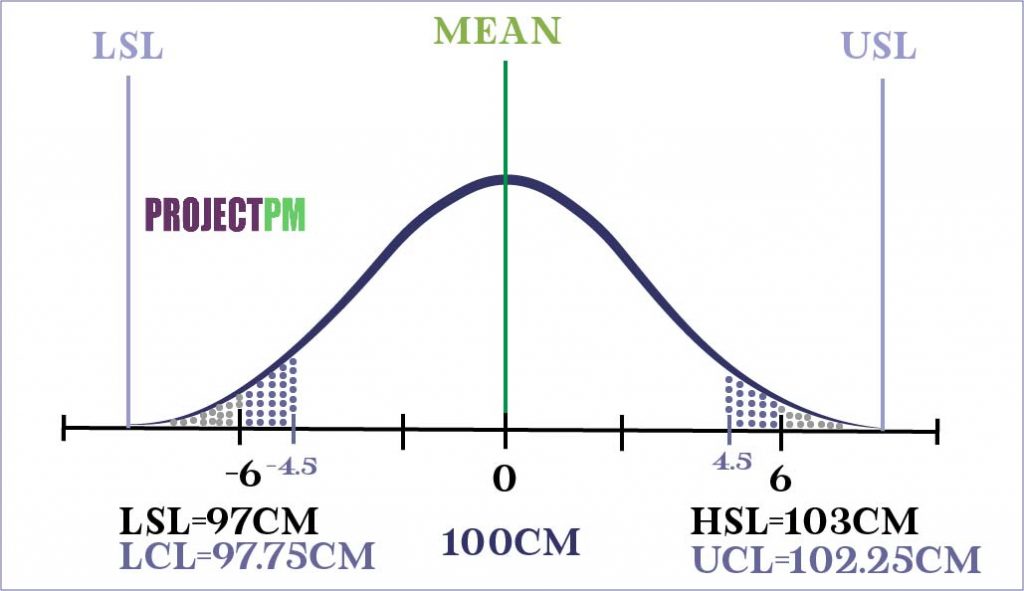

We have a manufacturing unit designed to get every piece for a length of 100cm.

Now you know not every piece can be exactly, and there are some variations in every process universally. We are going to control this higher variation by six sigma.

When we are going to apply six sigma, here, we will set our specification limits that are

Upper Specification Limit – 103

Lower Specification Limit – 97

in this case.

That means that we want a process where out of specification chance is 2 out of billion (0.00000000197). To get this, we must have 6 standard deviations far from the mean/target. We need to upgrade manufacturing units to that level.

Setting Control Limits

To get the above results, we have to set control limits to get a warning as soon as it approaches this area. These control limits are nothing but just an alert system though the product is well in range. In our case, we will set it like

- Upper Control Limit (UCL) – 102.25cm

- Lower Control Limit (LCL) – 97.75cm

How I got the above figures;

The experience shows that the process varies by much as 1.5 of standard deviation.

Since

- HSL = 6σ then UCL = 4.5σ

- LSL = 6σ then LCL = 4.5σ

I hope I am quite clear until now. Or you can see the below graph for more clarification.

Typically, industries set their average for the higher quality we have exponentially, and you may not require 6 sigmas or 7 sigmas.

Remember, 4 sigma is the industry average.

So, what does standard deviation tell us and help us in controlling the process?

- It is simply a measure of how close to the mean the actual data points are.

- It is a measure of spread as it tells us how wide or concentrated your data is.

Defects per million and Six Sigma Table

| Sigma Level | Defects per Million Opportunities – DPMO | Yeild% |

| 6 | 3.4 | 99.99966% |

| 5 | 230 | 99.977% |

| 4 | 6,210 | 99.38% |

| 3 | 66,800 | 93.32% |

| 2 | 308,000 | 69.15% |

| 1 | 690,000 | 30.85% |

Six Sigma Methodologies

We have two methodologies inspired by Deming’s PDSA (Plan–Do–Study–Act) Cycle. These methodologies have 5 phases each.

- DMAIC – for projects aimed at improving an existing business process.

- DMADV – for projects aimed at a new product or process designs.

Steps of DMAIC Process

- Define The first phase; you need to set all the goals after finding the problems to handle.

- Measurement: Here, you study the process, set limits, and map out the current process.

- Analysis: You deeply analyze the outputs of the applications of your settings.

- Improvement: You will see the improvement of your process or repeat the above steps.

- Control: Here, you maintain the process improved by the above phases & get the fruits.

Steps of DMADV or DFSS Process

The DMADV is also known as DFSS- Design For Six Sigma.

- Define: Define your goals here in this phase as per demand

- Measure: Measure out all the critical areas of the process

- Analyze: to make out a proper development and re-design or find alternatives

- Design: Find out the best available alternative

- Verify: Do a cold test and set up pilot runs once all done to get the approval and continue.

Six Sigma Belts

Six Sigma organizes its staff according to a system of ‘belts’ that rank staff according to their role in the company and their ascendancy level. These roles may include the following:

- Green Belts – lowest-ranked and are principally responsible for the implementation of project aims.

- Black Belts – supervise green belts, and their primary focus is on the execution of projects.

- Master Black Belts – broadly responsible for the general, company-wide implementation of the strategy. Act as mentors to black and green belts.

- Champion – oversees all practices of the enterprise whilst guiding all lower-ranking black belts.

Lean Six Sigma

The combination of Six Sigma with ‘lean manufacturing’ lead to the creation of ‘Lean Six Sigma,’ a methodology that strives to eliminate wastage. Several prominent businesses, such as General Electric, Motorola, and Toyota, employ Lean Six Sigma and have described various key points that should be followed. Although these may seem like tricky objectives, they can be explained in the following terms:

1. Commitment to your project’s scope and goals can only be achieved through consistent action and planning.

2. Rewards should be linked to performance; promotion should be closely associated with training-related competency.

3. Lean Six Sigma should form a leadership development program that prepares future company managers.

4. Goals should be customer-focused and goal-driven; feedback should challenge current thinking within the project’s framework.

5. It is critical that strategies remain focused, paying close attention to the project’s objectives as a whole. Frequent revisions, even when necessary, should not lack direction.

6. The value that Lean Six Sigma brings to a project means that it should be considered an investment rather than an expense.

7. Lean Six Sigma should incorporate alternative but complementary strategies that are recognized as industry standards.

Six Sigma Disadvantages

Six sigma is considered an old methodology, and no doubt, it needs lean management to stay in. The following are the major disadvantages of having only six sigma in action;

- It needs a team with proper training.

- Six sigma adoption needs team buy-in, which is tough in bigger teams.

- The overall cost is much higher at the start of six sigma implementation.

- Specific missions of companies are sacrificed initially to implement six sigma properly.

- Six Sigma is a time-consuming tool.

- Implementation of six sigma is a time-taking activity that needs patience to get results.

- Six Sigma is a methodology that needs to scrap the previously adopted methodology.

- Six Sigma focuses on a strict process that is not as per new industry trends.

Wrap Up

Six Sigma has revolutionized process management, such that its data collection, quality controls, and implementation strategies are recognized as both economical and valuable. Indeed, many corporate bodies seek to emulate this approach within their own organizations. Implementing Lean Six Sigma should highlight a company’s common vision, thereby enabling a unified workforce. After all, a business leader who can articulate a clear and uncompromising view of their strategy will be a powerful driving force for success. A clear mission statement will play a significant role in aligning efforts and inspiring action within all strata of your company.